Estimating the cost of a BOM

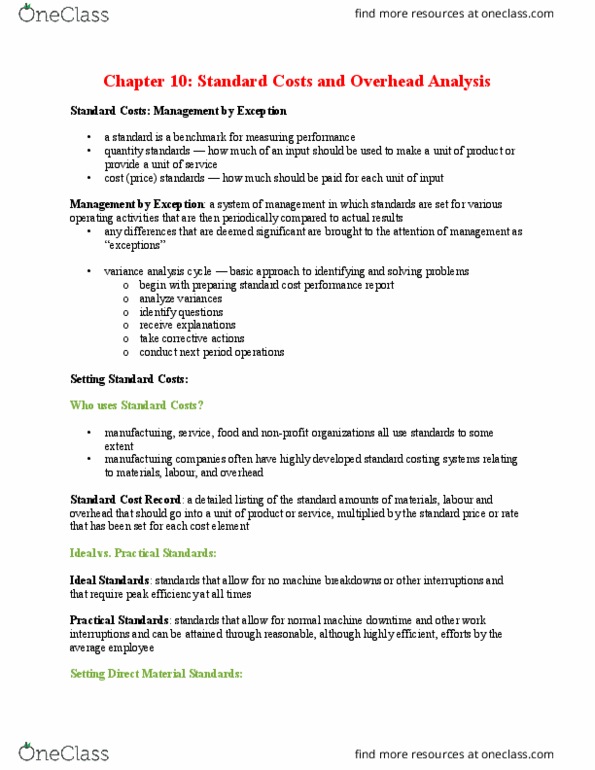

The varied definitions of standard costing lay emphasis on the determination and use of standard price and hence it’s desirable to understand the that means of ‘Standard Cost’. Actually speaking, normal prices are these prices that are decided upfront for a normal degree of effectivity of operation and that are used periodically as a foundation for comparability with actual prices. These could also be termed as ‘commonsense costs’ reflecting one of the best judgment of administration as to what prices should be if the enterprise operations are performed with high diploma of effectivity.

It helps to plan for acquisition orders and reduces the potential of errors. If it isn’t accurate, it can cause production to halt or cause delays, which enhance operation prices because a company has to find the lacking parts, start one other production order or cope with customer returns. There are each advantages and drawbacks to utilizing a standard costing system.

(i) There ought to be output or production of enough quantity of some commonplace product. The main objective of ordinary prices is to provide administration with data on the day-to-day management of operations. Standard prices are predetermined prices to supply a foundation for simpler control over prices. The requirements costs provide a sign of the criterion by which something may be analyzed.

What are the types of standard?

A BOM list is necessary when ordering replacement parts and reduces possible issues if product repairs are required. It helps to plan for acquisition orders and reduces the possibility of errors. An engineering bill of materials defines the design of the finished product.

Ideal Standards:

Why BOM is required?

A bill of materials or product structure (sometimes bill of material, BOM or associated list) is a list of the raw materials, sub-assemblies, intermediate assemblies, sub-components, parts, and the quantities of each needed to manufacture an end product.

This additionally ensures that common checks are made upon the expenditure incurred. Standard value is set for a traditional level of efficiency of operation.

The major benefits to utilizing a standard costing system are that it can be used for product costing, for controlling costs, and for determination-making functions. In accounting, a regular costing system is a device for planning budgets, managing and controlling prices, and evaluating price administration efficiency. Current requirements are standards which are established to be used over a short time frame, and are related to current conditions. They characterize present prices to be expected from environment friendly operations.

Responses to Standard Costing System

These standards don’t anticipate best efficiency; they are tough, however attainable to achieve. An alternative purpose for the fee sheet idea is to make use of it as the premise for a quote to a buyer, often for the manufacture of a custom product. In this case, the price sheet contains the most effective estimates of the corporate’s estimators for the requested product, with particulars for every of the previously indicated expense line gadgets. The development of a price sheet could be a major production, particularly whether it is compiled by hand. Even if it is drawn from a database of compiled costs, a price accountant should nonetheless evaluate it for duplicate, missing, or incorrect entries earlier than issuing it.

It is feasible to save lots of and hold a multi-stage BOM excel sheet, however as you possibly can imagine, it is troublesome to add in your potentialproduct variants. At the top of your tree shall be your finished good (or parent product/level 0), and branching off from there will be all your subassemblies and their relation to the parent product. It’s important Bookkeeping to know what is a subassembly, as this is a key part of growing your multi-degree BOM. Asubassemblycan also perform as a completed product too, which may be bought separately to clients or used to complete the development of another product. In electronics, the BOM represents the record of components used on the printed wiring board or printed circuit board.

What is a cost sheet?

To find the standard cost, you first compute the cost of direct materials, direct labor, and overhead per unit. Then you add up these amounts. To calculate the standard cost of direct materials, multiply the direct materials standard price of $10.35 by the direct materials standard quantity of 28 pounds per unit.

Once you’ve created these MO’s, should you return to the make screen, you possibly can examine on the status of every of your assembly’s production status. In the above instance, we don’t have the elements (subassemblies) to begin manufacturing, and we’ll have to create a producing order (or place an order from the provider in the case of the frame) for each of the subassemblies. However, if you select the materials tab, you can see all of the components which have been used to make those subassemblies.

- Asubassemblycan also perform as a finished product too, which can be sold separately to prospects or used to complete the development of one other product.

- The difference between commonplace cost and precise value are called variances.

- This is the total of costs concerned in manufacture, building and fabrication of items of production.

- A manufacturing bill of materials contains all of the assemblies and parts required to assemble a finished item ready to be shipped.

- A price range often refers to a department’s or a company’s projected revenues, costs, or bills.

- Standards are set on a standard capability basis which represent a volume that averages out the corporate’s peak and slack intervals.

What is normal costing?

The difference between normal cost and precise value are called variances. For correct management bookkeeper and efficiency measurement in the organization, variances must be measured and analyzed.

Types of Standards

If the standards are constantly to being studied and revised they function a reliable basis for evaluably efficiency and management costs https://cryptolisting.org/. Standard prices serve as a yardstick towards which actual costs may be compared.

Once the design of the circuit is accomplished, the BOM record is handed on to the PCB structure engineer as well as the element engineer who will procure the parts required for the design. Material necessities planning is among the many first software-primarily based built-in data techniques designed to enhance productiveness for businesses. A BOM record is necessary when ordering replacement elements and reduces attainable issues if product repairs are required.

With a regular costing system, the employees are additionally well aware of the set requirements, in order that they at all times attempt to meet the requirements. Ideal Standards, additionally known as perfection standards, are established on a most efficiency degree with no unplanned work stoppages. They represent the level of attainment that could be reached if all the conditions were good all the time. (ii) The methods, operations and processes of production must be able to standardisation.

The worker can report the quantity of extra product during manufacturing. – For instance, while the engineering BOM states thata 1-meter stick accommodates 1-meter of a stick,the manufacturing BOM will say thatmaking of a 1-meter stick consumes 1.2 meters of a stick (incl. zero.2m of scrap). – The assembly structure is usually simplified, if possible, even to a single stage. Standard costing offers comparative info to the managers and directors concerning the inside prices of various departments. Improvement in labor efficiency and wastage management will at all times assist the administration to regulate their product price.

What is the actual cost method?

standard-sized. A device, item, object or product created to an official or industry agreed standard size. Shipping containers are created and manufactured to a standard-sized height, width and length so they can fit accurately onto a boat, ferry, ship, truck or lorry.

Cost sheet

A price sheet is often issued along with an explanatory page that factors out any uncommon prices incurred or variances that administration ought to pay attention to. Each item has its personal precise https://cryptolisting.org/blog/what-is-capital-inventory-in-economics cost, which it was bought with, saved in the inventory lot particulars. the Matrix BOMfunctionality is enabled and the BOM includes a relation or some parameter adjustments the number of raw supplies.

Nearly all corporations have budgets and plenty of use standard cost calculations to derive product prices, so it is apparent that commonplace costing will discover some makes use of for the foreseeable future. In specific, normal costing supplies a benchmark against which administration can evaluate precise performance.

Comentarios recientes